Lighting Resin

We have an internal Lighting Resin Line through which we make our products in the catalog.

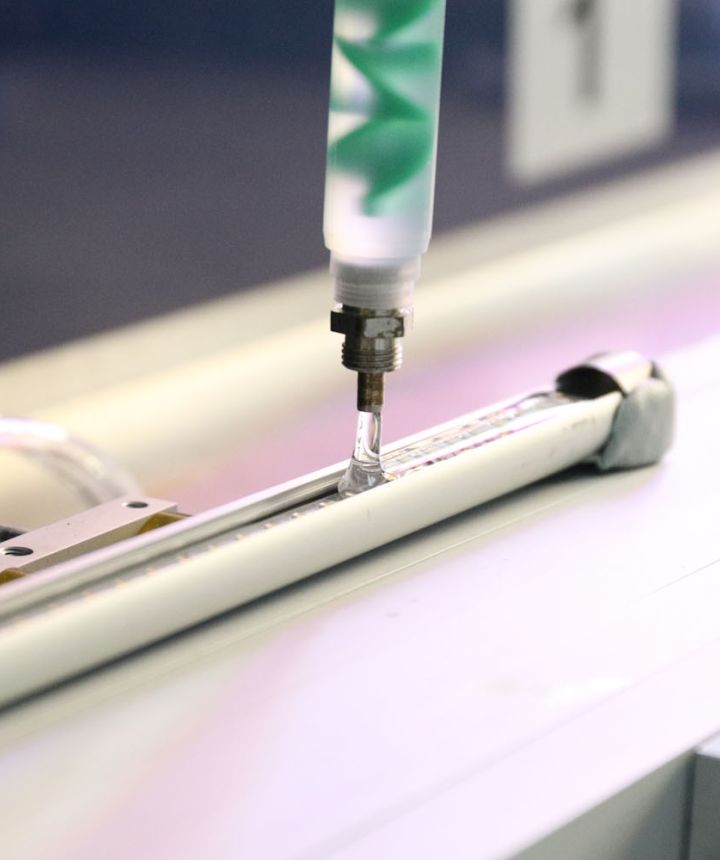

Resin is the process that incorporates the electronic part of our LED products in a protective volume that can be rigid or flexible, transparent, opaque or in different colors. This resin process guarantees our products for LED lighting protection from external agents in compliance with International Protection standards (eg. IP65-68), anti-UV, anti-yellowing and anti-corrosive salt filter.

The resins we use are of the two-component polyurethane type and certified. Through controlled channeling times, the resins reach the right degree of mixing, thus obtaining a perfect result.

This type of service, as well as the photometry service, in addition to being applicable to our outdoor product catalog, can be carried out on behalf of third parties in a short time.

We also offer the possibility of resining LED strips, electronic boards, or any electronic device inside a container and part of the wiring that connects the device to the outside.

Our resin coating service, being always in operation and therefore constantly controlled and optimized, allows us to respond to requests promptly and with a high degree of quality without aesthetic defects.

Lighting resin coating service made by Led Italy srl

The resin coating department is another excellence of the LED ITALY production department.

Three different automated lines whose production benches have the capacity to manufacture linear components of a length even of the order of tens of meters guarantee in which the two-component polyurethane resins of very high quality and resistant to UV radiations, injected in shape liquid, once layered in various passages they give life to the finished product in the many different variants without the slightest qualitative difference, transparent resin, opal resin or crystalline resin with IK10 impact resistance characteristics compatible with the drive-over use of the product.

Controlled stratification polyurethane resin, of different types epending on the model, allows the creation of an intrinsically waterproof linear flexible element.

The fundamental requisites that all the products in the collection satisfy are durability, high resistance to corrosive agents, and a large range of operating temperatures, between -30 / + 55 ° degrees. All these aspects have allowed LED ITALY to offer a very wide range that exceeds the limits of yellowing, premature aging and overheating typical of classic products on the market.

Thanks to the specific construction philosophy common to all the products of the Linea Luce Flex collection, the linear elements are intrinsically waterproof and suitable in outdoor spaces, in damp spaces, exposed to the elements and suitable for immersion having passed the homologation tests of the resins which give the product the IP68 degree. An adequate choice between dedicated power cables and accessories in the range allows the product to be used in IP68 applications such as fountains and swimming pools.